| Category | Product name/model | Key features | Application field |

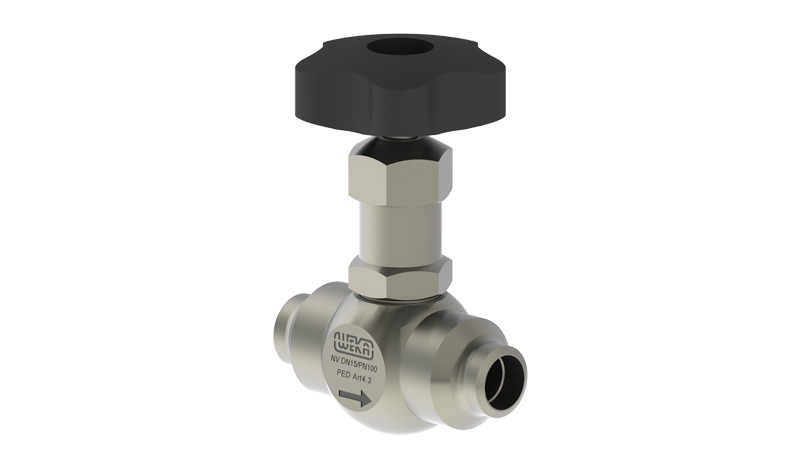

| High-pressure valve | High-pressure needle valve (NV) | DN4-DN15, PN110/420;Temperature range: -200°C to +100°C End: Neck welding, threaded welding or butt welding; Sealing: Polytetrafluoroethylene or graphite cover bag | Branch connection, instrument interface, cleaning system; Applicable gases: nitrogen, air, argon, etc. Low-temperature environment (as low as -250°C |

| High-pressure needle valve - Oxygen series (CNV) | DN8-DN15, PN80-110;Temperature range: -196°C to 90°C End: Butt welding or socket welding; Sealing: Graphite cover wrapped with BAM protective material | Branch connection, instrument interface, cleaning system; Applicable gases: Gas and liquid oxygen; A pure gas cleaning procedure is required |

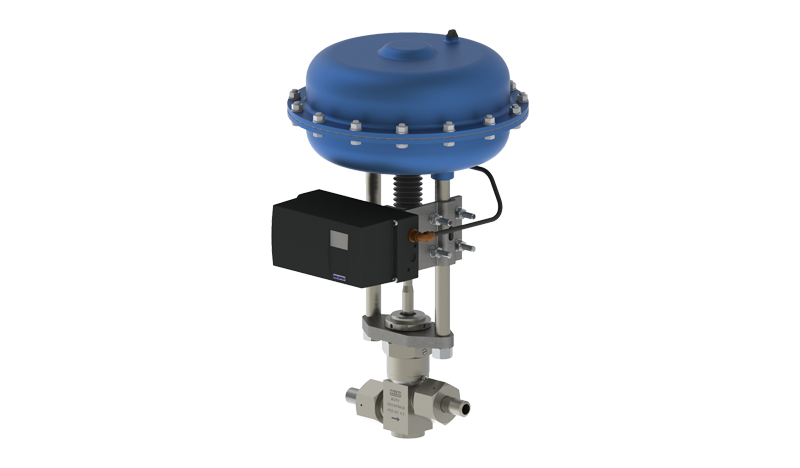

| High-pressure process valve | DN6-DN25(PN420)、DN6-DN50(PN280)、DN6-DN100(PN100);Manual or pneumatic lift valve stem; The valve seats are interchangeable. Sealing: Double sealing with spring-type PTFE V-rings and O-rings; Blowout prevention structure Temperature range: -250°C to +50°C | Process control valve Applicable gases: nitrogen, air, compressed natural gas, liquefied natural gas, helium, hydrogen; Low-temperature environment (as low as -250°C |

| High-pressure hydrogen valve | DN6-DN25, PN640;Manual or pneumatic lift valve stem; The valve seats are interchangeable. Sealing: Double sealing with spring-loaded PTFE V-rings and O-rings; Blowout prevention structure Temperature range: -250°C to +50°C | Process control valves and safety shut-off valves; Applicable gas: high-pressure gaseous hydrogen; Low-temperature environment (as low as -250°C |

| 1000bar Valve | DN6-DN15, PN1000;Manual or pneumatic lift valve stem; Metal seal of the valve seat Sealing: Double sealing with 2 spring-loaded PTFE V-rings; Blowout prevention structure Temperature range: -250°C to +50°C | Process control valve Applicable gas: high-pressure gaseous hydrogen; Low-temperature environment (as low as -250°C); The safety of hydrogen operation has been verified |

| High-pressure check valve | DN6-DN25, PN640;One-way valve design The valve seats are interchangeable. Temperature range: -50°C to +50°C | Process control valves and safety shut-off valves; Applicable gas: high-pressure gaseous hydrogen |

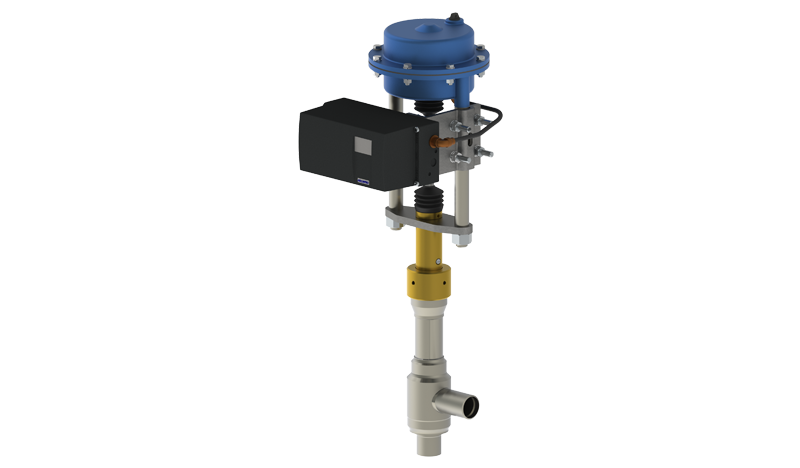

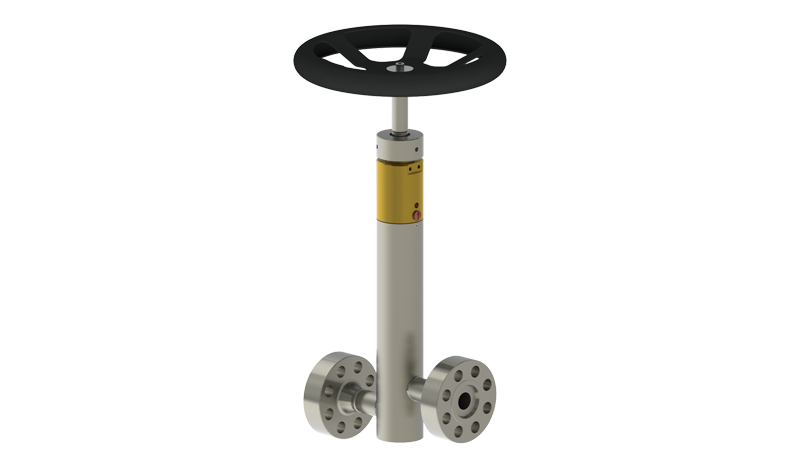

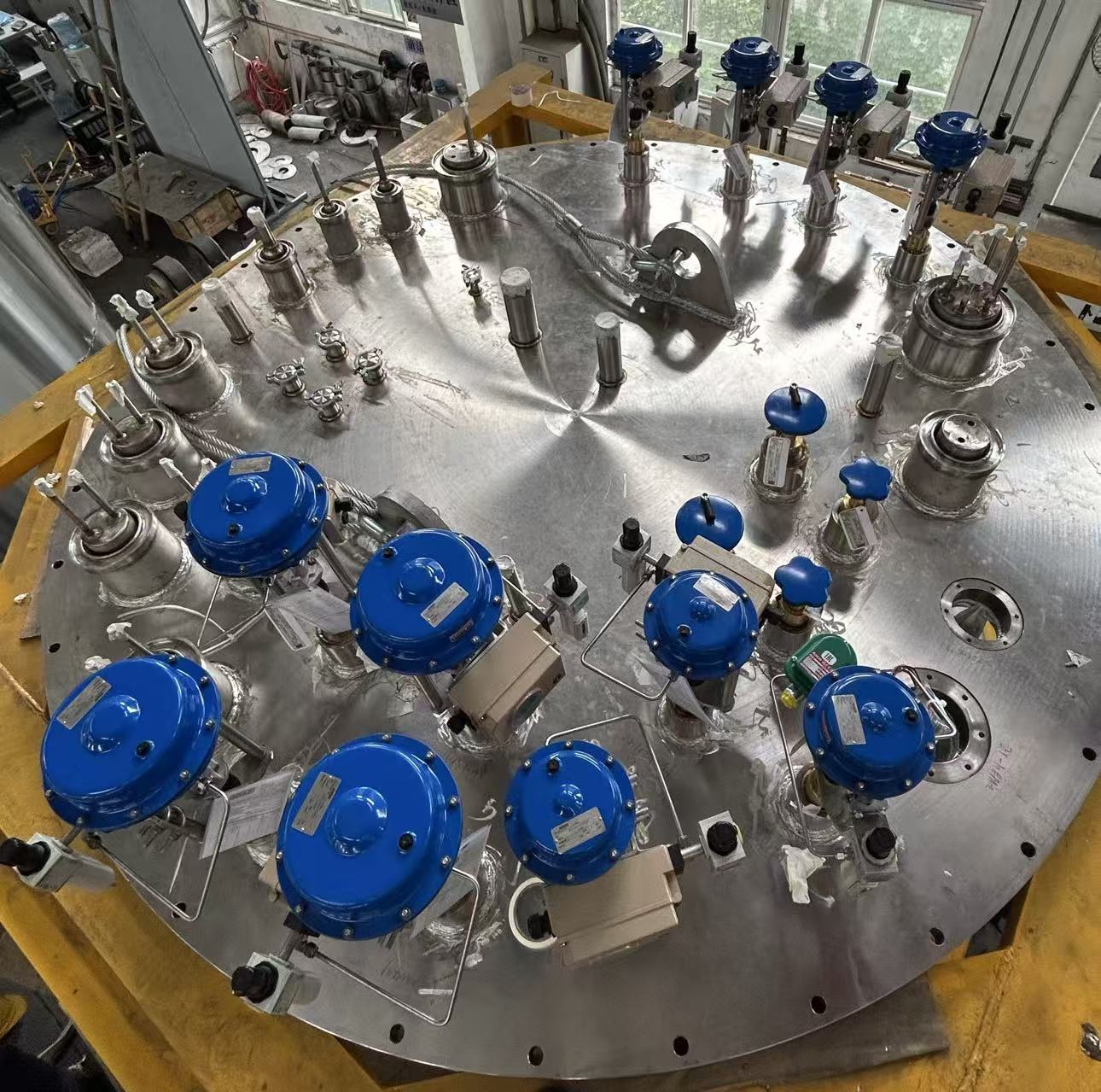

| Cryogenic valves | Low-temperature top-less valve | DN20-DN80 (larger available), PN25; Manual or pneumatic lift valve stem; The valve seats are interchangeable. Sealing: Bellows or four-ring sealed valve stem; Temperature range: -271°C to +50°C | Process valve; Applicable gases: nitrogen, air, oxygen, argon, etc. Installation location: Inside or outside the vacuum insulated valve box |

| Low-temperature four-ring sealed valve | DN6-DN150 (up to DN300), PN25; Manual or pneumatic lift valve stem; The valve seats are interchangeable. Top loading design; Sealing: Four-ring sealed valve stem; Temperature range: -271°C to +50°C | Process valve; Applicable gases: nitrogen, air, oxygen, argon, etc. Installation location: Inside or outside the vacuum insulated valve box; It can be welded onto the vacuum insulated valve box |

| Low-temperature bellows sealed valve | DN6-DN150 (up to DN300), PN25; Manual or pneumatic lift valve stem; The valve seats are interchangeable. Top loading design; Sealing: Corrugated pipe ring seal valve stem; Low heat load; Temperature range: -271°C to +50°C | Process valve; Applicable gases: Helium, hydrogen; Installation location: Inside the vacuum insulated valve box; The standard solution of Linde and AirLiquide helium liquefaction apparatus |

| Warm bellows sealed valve | DN6-DN150 (up to DN300), PN25; Manual or pneumatic lift valve stem; The valve seats are interchangeable. Top loading design; Sealing: Corrugated pipe ring seal valve stem; Temperature range: -271°C to +50°C | Process valve; Applicable gases: Helium, hydrogen; Installation location: Outside the vacuum insulated valve box; The standard solution of Linde and AirLiquide helium liquefaction apparatus |

| Low-temperature double-sealed valve | DN6-DN150 (up to DN300), PN25; Manual or pneumatic lift valve stem; The valve seats are interchangeable. Top loading design; Sealing: Double sealing (bellows and O-rings or double bellows); Anti-loosening connection Temperature range: -271°C to +50°C | Process valve; Applicable gases: helium, deuterium, tritium in the sub-atmosphere; Installation location: Outside the vacuum insulated valve box |

| Low-temperature specially designed valves | Including 3/2-way cryogenic valves, valves with external electronic components, combined stop valves and check valves, compact pneumatic valves, and valves with helium actuators; Temperature range: -271°C to +50°C | Process valve; Applicable scenarios: High magnetic field or radiation environments, outside vacuum insulated valve boxes; Special applications such as helium execution |

| Low-temperature component | Low-temperature check valve | Size: DN6-DN200, PN25/PN40; Low cracking pressure; Temperature range: Suitable for low temperatures | Recovery pipeline check valve; Applicable gases: Low-temperature gases (such as nitrogen, helium); Apply from room temperature to PN4 |

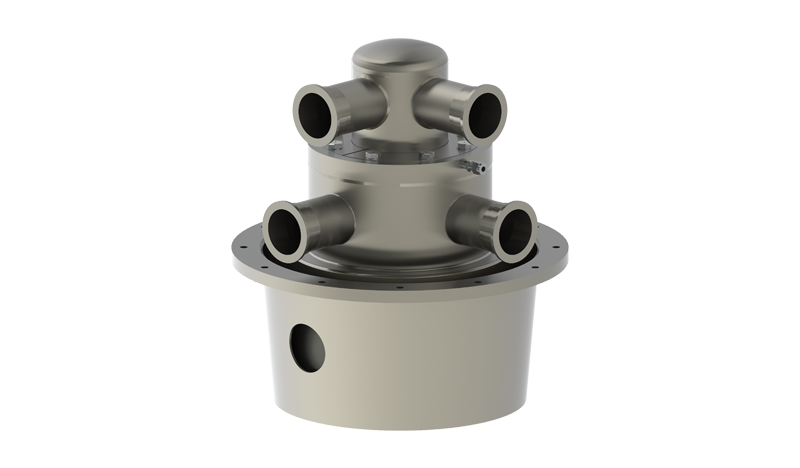

| Low-temperature transmission line connector | Based on the "Johnston" design; Size: DN6-DN200, PN25; Type: Standard single-wire couplings (male and female couplings and blind plugs), multi-coaxial couplings; Optional designs: Blind plate ball valve, X-ray protection seal, etc | Application of low-temperature couplings Installation method: Vertical or horizontal (with spring cold seal); Applicable scenarios: Gas transmission lines; High-voltage isolation can reach up to 3.0kV |

| Special valve | Battig special valves | DN6-DN50 (PN280), DN6-DN100 (PN100); Manual or pneumatic lift valve stem; The valve seats are interchangeable. Sealing: Bellows sealing or gland sealing; Temperature range: -270°C to +50°C | Process valve; Applicable gases: nitrogen, air, compressed natural gas, liquefied natural gas, helium, hydrogen; Low-temperature environment (as low as -250°C); Original spare parts |

Phone: 13764553949

Phone: 13764553949 Fax: 13764553949

Fax: 13764553949 Email: howard.huang@sh-easytech.com

Email: howard.huang@sh-easytech.com Address: Room 2007, Building 3, Jiefang Mansion, Zhucheng Road, Xinzhuang Town, Minhang District, Shanghai

Address: Room 2007, Building 3, Jiefang Mansion, Zhucheng Road, Xinzhuang Town, Minhang District, Shanghai