| Category | Core module | Core function | Technical highlights | Compatible gas |

| High-purity pipeline system | Stainless steel pipe(316L/BA/EP) | Achieve ultra-high cleanliness gas transportation to avoid particle contamination and gas adsorption | Inner wall roughness Ra≤0.4μm(EP) | Electronic specialty gases (such as SiH₄, NH₃), high-purity nitrogen, hydrogen |

| Welding method: Fully automatic track welding (inert gas protected) |

| Rate of leakage≤1×10⁻⁹ Pa·m³/s |

| Pipe fittings (ferrule/welded type) | Ensure that the system has no dead corners for connection to reduce the risk of gas retention | Material: 316L stainless steel (electrolytic polishing) | Semiconductor lithography gas, laboratory standard gas |

| Sealing method: VCR metal surface seal/Double ferrule (without elastomer) |

| Applicable pressure: Vacuum to 3000psi |

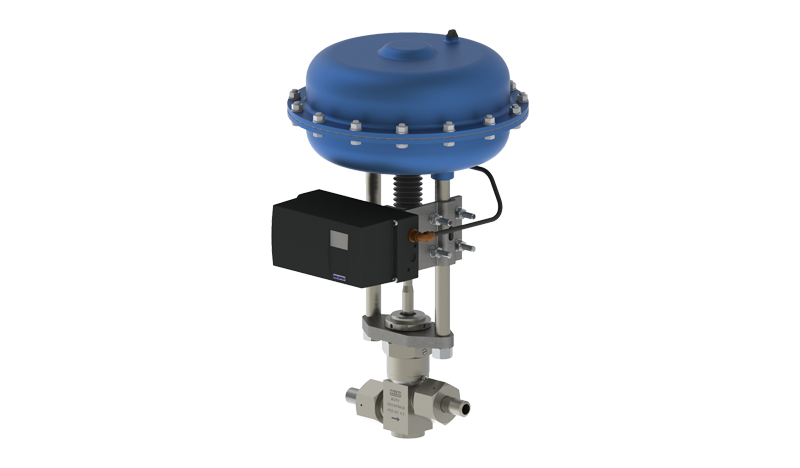

| Special valve assembly | High-purity diaphragm valve | Zero dead volume cut-off, avoiding medium residue and cross-contamination | Valve body material: 316L (EP grade) | Ultra-high purity oxygen, medical-grade nitrous oxide |

| Diaphragm material: PTFE/EPDM (Temperature resistance -40℃ to +180℃) |

| Operation mode: Manual/Pneumatic/electric |

| Gas pressure reducer | Precisely control the downstream gas pressure to ensure the stability of the system pressure | Adjustment accuracy: ±0.5% full scale | Gas cylinder manifold, gas distribution panel |

| Import pressure: Up to 3000psi |

| Outlet pressure range: 0 to 1000psi (Multiple Settings available) |

| Gas purification equipment | High-efficiency filter (ULPA grade | Remove particles ≥0.1μm from the gas, with a filtration efficiency of ≥99.999% | Filter element material: PTFE/ borosilicate fiber | All high-purity gas terminals are filtered |

| Maximum flow rate: 500Nm³/h (single tube) |

| Differential pressure alarm function (optional |

| Dehydration/deoxidation purification module | Reduce the H₂O and O₂ impurities in the gas to the ppb level | Dehydration depth: ≤-100℃ dew point | High-purity argon gas for the electronics industry and high-purity nitrogen for laser cutting |

| Deoxidation depth: ≤5ppb |

| Regeneration method: Thermal regeneration/inert gas purging |

| Monitoring and control system | Online purity analyzer | Real-time monitoring of the concentration of trace impurities (H₂O/O₂/ particles) in the gas | Detection accuracy: ppb grade (H₂O/O₂) | The main pipeline for specialty gas transportation and the outlet of the gas purification system |

| Response time: ≤10 seconds |

| Data output:4-20mA/RS485 |

| Pressure/flow monitoring unit | Continuously monitor pipeline pressure and flow, and automatically alarm in case of abnormal conditions | Pressure accuracy:±0.1%FS | Gas distribution system, gas intake control for reaction vessels |

| Flow range:0.1~1000Nm³/h(Mass flowmeter) |

| Support interlock control output |

Phone: 13764553949

Phone: 13764553949 Fax: 13764553949

Fax: 13764553949 Email: howard.huang@sh-easytech.com

Email: howard.huang@sh-easytech.com Address: Room 2007, Building 3, Jiefang Mansion, Zhucheng Road, Xinzhuang Town, Minhang District, Shanghai

Address: Room 2007, Building 3, Jiefang Mansion, Zhucheng Road, Xinzhuang Town, Minhang District, Shanghai