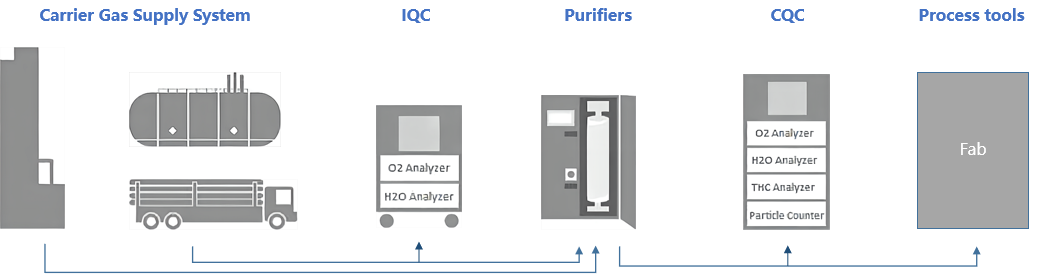

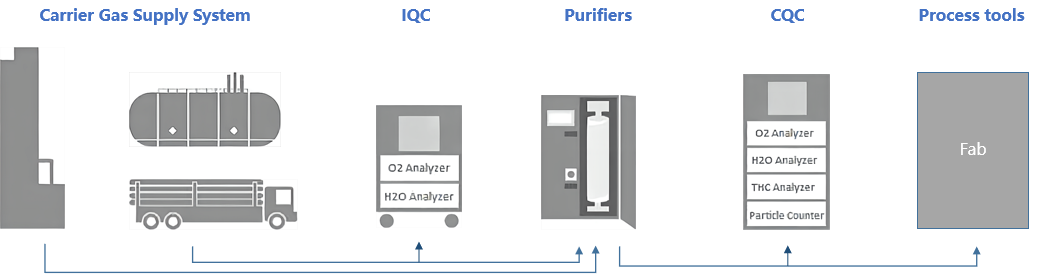

Gas continuous online analysis system: namely CQC (Continually Quality Control)

With the rapid development of the electronics industry, the purity requirements for bulk gases are getting higher and higher. Therefore, the detection of gas purity is extremely important, and thus a stable set is needed

A reliable continuous gas analysis system is an indispensable part of the gas supply chain. Usually, the system continuously detects N2, H2, O2, Ar, He, CDA, etc

The purity of the main gas is ensured by detecting the impurity content in it to guarantee the quality of the gas. Common impurities include O2, H2O, Partical, THC, CO, CO2, etc.

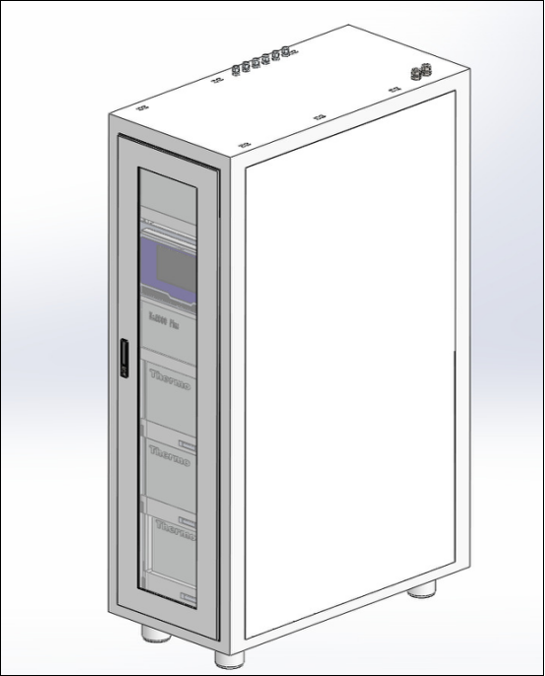

CQC will continuously and in real time measure the content of impurities in the gas and display and record the relevant data. When abnormal impurity content is detected, an alarm can be issued promptly.

And record data in real time. This will reduce the losses of customers and provide assistance for subsequent investigations.

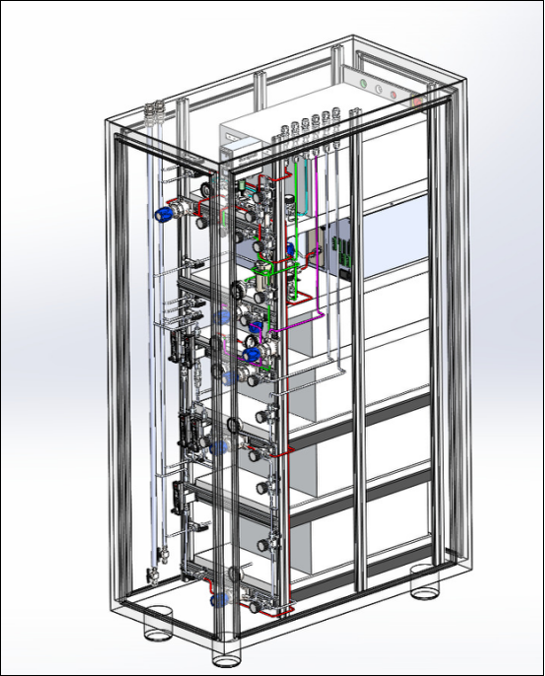

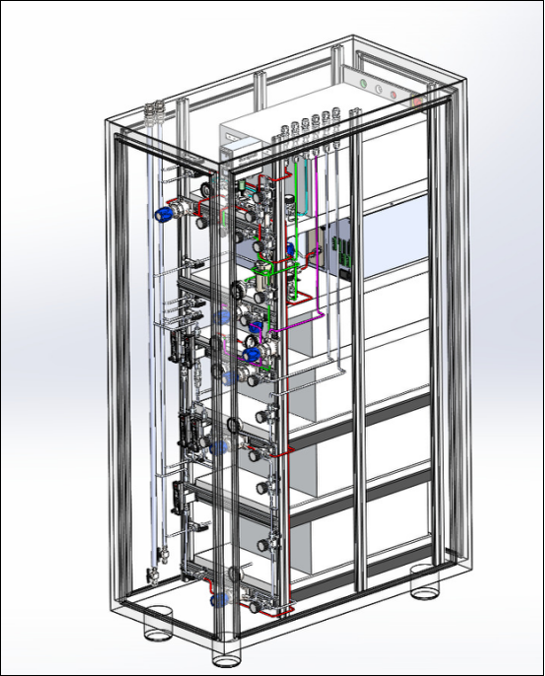

The composition of a continuous gas analysis system

● Low-precision IQC is generally used at the outlet of bulk gas stations and the front end of purifiers, requiring a measurement progress of 0.01ppm to 1ppm. An IQC is generally composed of a water meter, an oxygen meter, a cabinet and a recording computer.

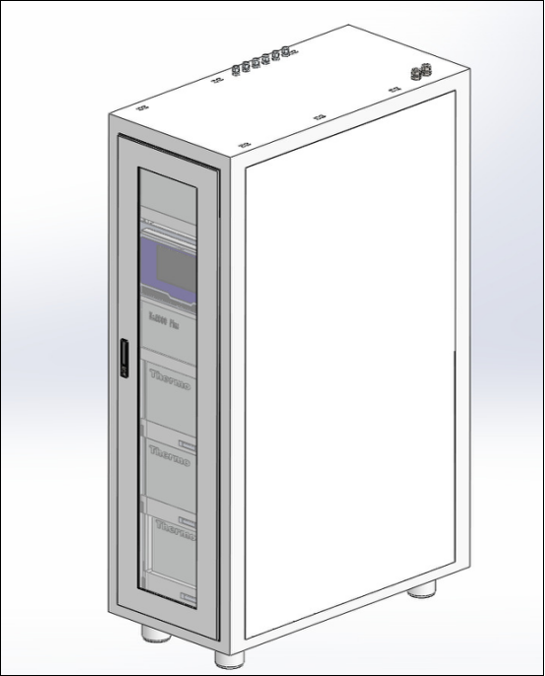

● High-precision CQC, typically located at the rear end of the purifier, requires a measurement progress of 1ppb or less.

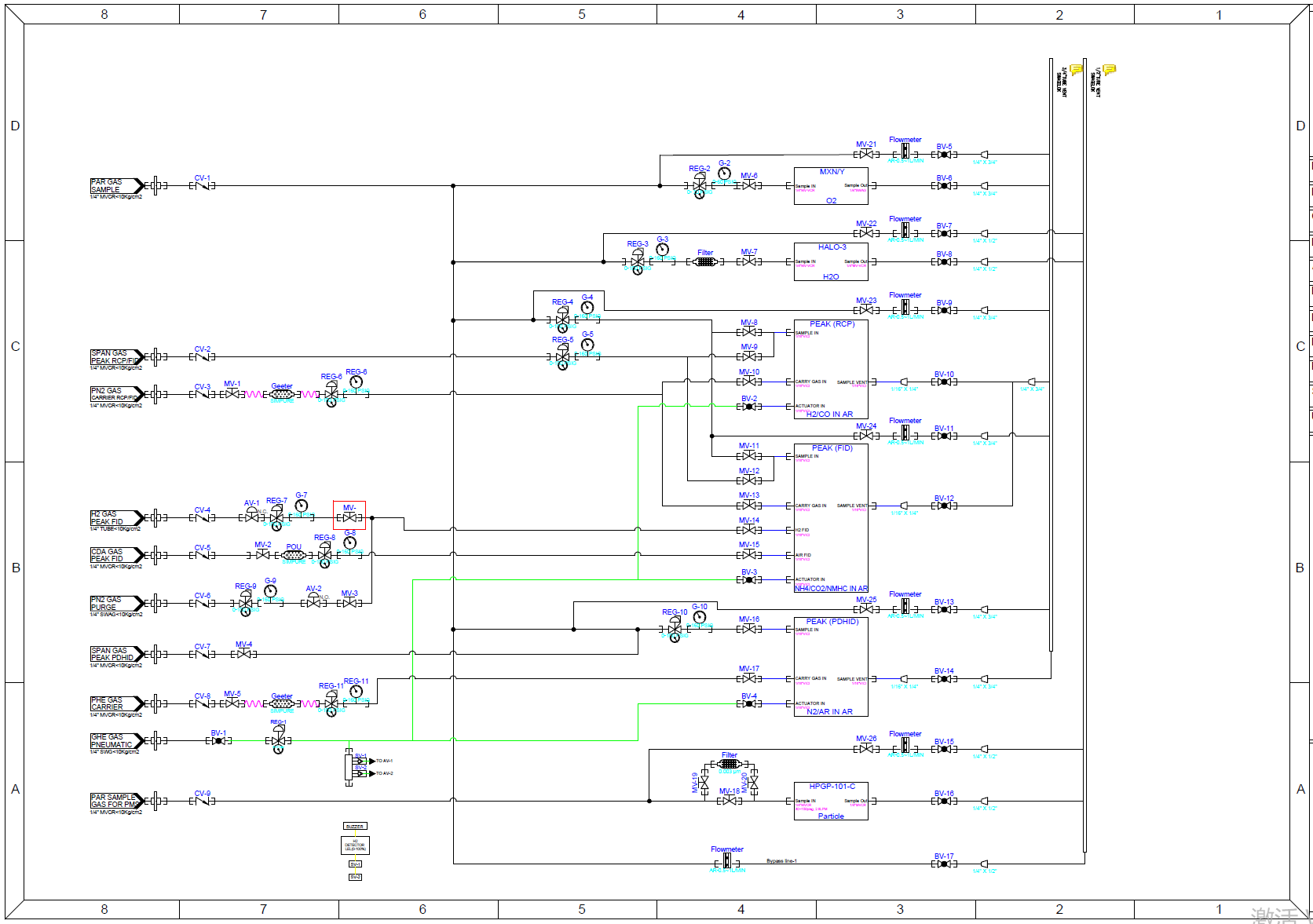

A CQC is generally composed of a water meter, an oxygen meter, a particle analyzer, a gas chromatograph, a cabinet and a recording computer.

Technical advantages: Instrument selection, pipeline design, communication system design

● The equipment selection is economical, saving costs for customers and bringing value

● The compliance of equipment selection is applicable to the compliance requirements of different countries and regions

● Special designs and measures for ultra-high pressure and ultra-low temperature sample gases

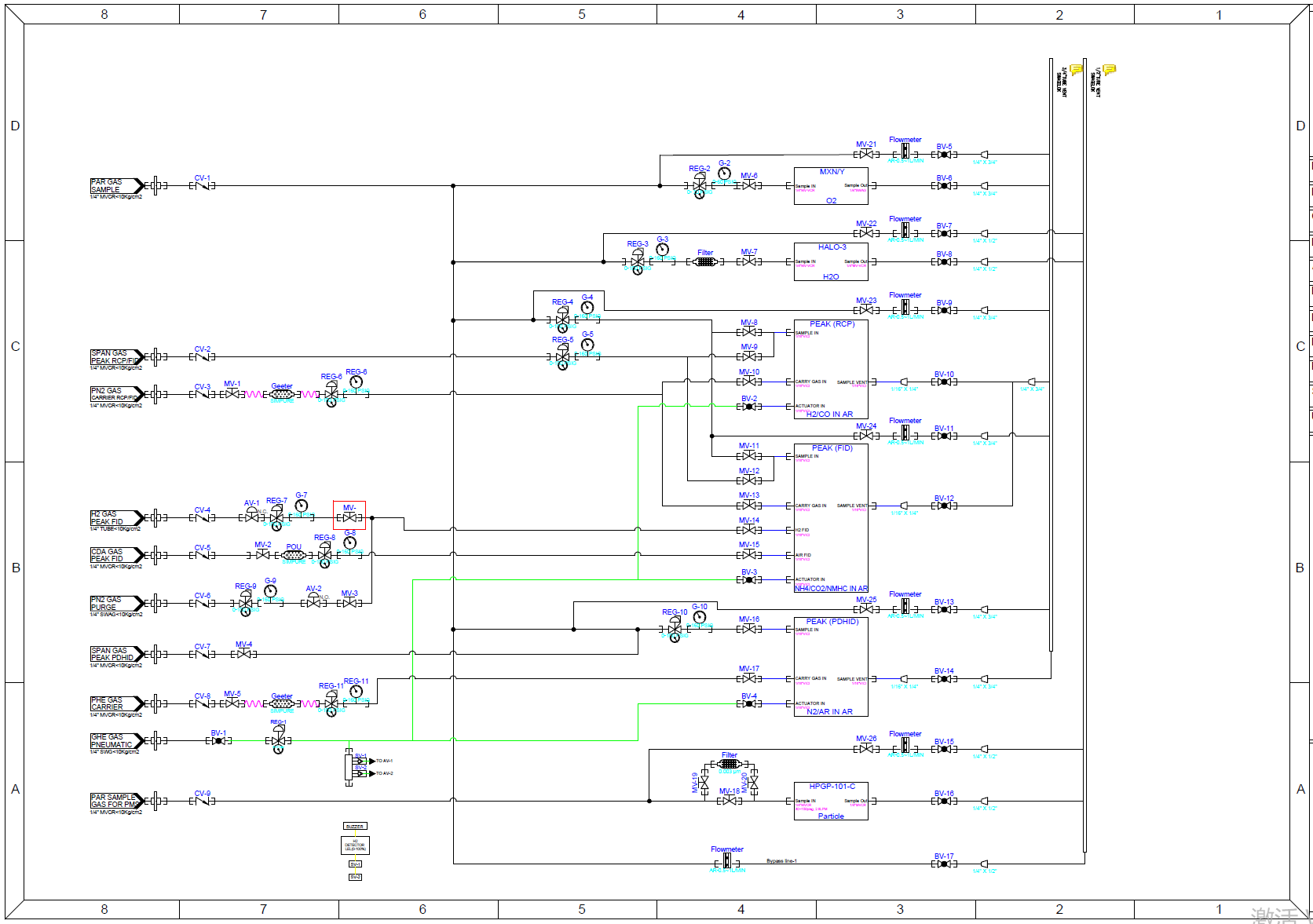

● The pipeline design is reasonable, reducing the dead zones of pipelines in the cabinet and facilitating pipeline purging

● Switching design enables one set of analysis system to analyze multiple sample gases

● Linkage operation of the analysis system, gas purifier and gas-liquid storage tank

| Application field | Key detection parameters | Typical configuration equipment | Core value |

Semiconductor bulk gas supply | Moisture, oxygen, particulate matter, hydrocarbons (ppb grade) | Moisture meter (SERVOMEX DF750), oxygen analyzer (DF550), particle analyzer (PMS), gas chromatograph (PEAK RCP&FID) | Ensure the purity of the gas in the photolithography/ion implantation process and improve the yield of chips |

|

The gas plant conducts purification and testing | Trace impurities such as CO, CO₂, and H₂S | Gas chromatograph (Pulsed Helium ionization Detector PDD | Verify the performance of the purifier to avoid downstream contamination |

|

Phone: 13764553949

Phone: 13764553949 Fax: 13764553949

Fax: 13764553949 Email: howard.huang@sh-easytech.com

Email: howard.huang@sh-easytech.com Address: Room 2007, Building 3, Jiefang Mansion, Zhucheng Road, Xinzhuang Town, Minhang District, Shanghai

Address: Room 2007, Building 3, Jiefang Mansion, Zhucheng Road, Xinzhuang Town, Minhang District, Shanghai